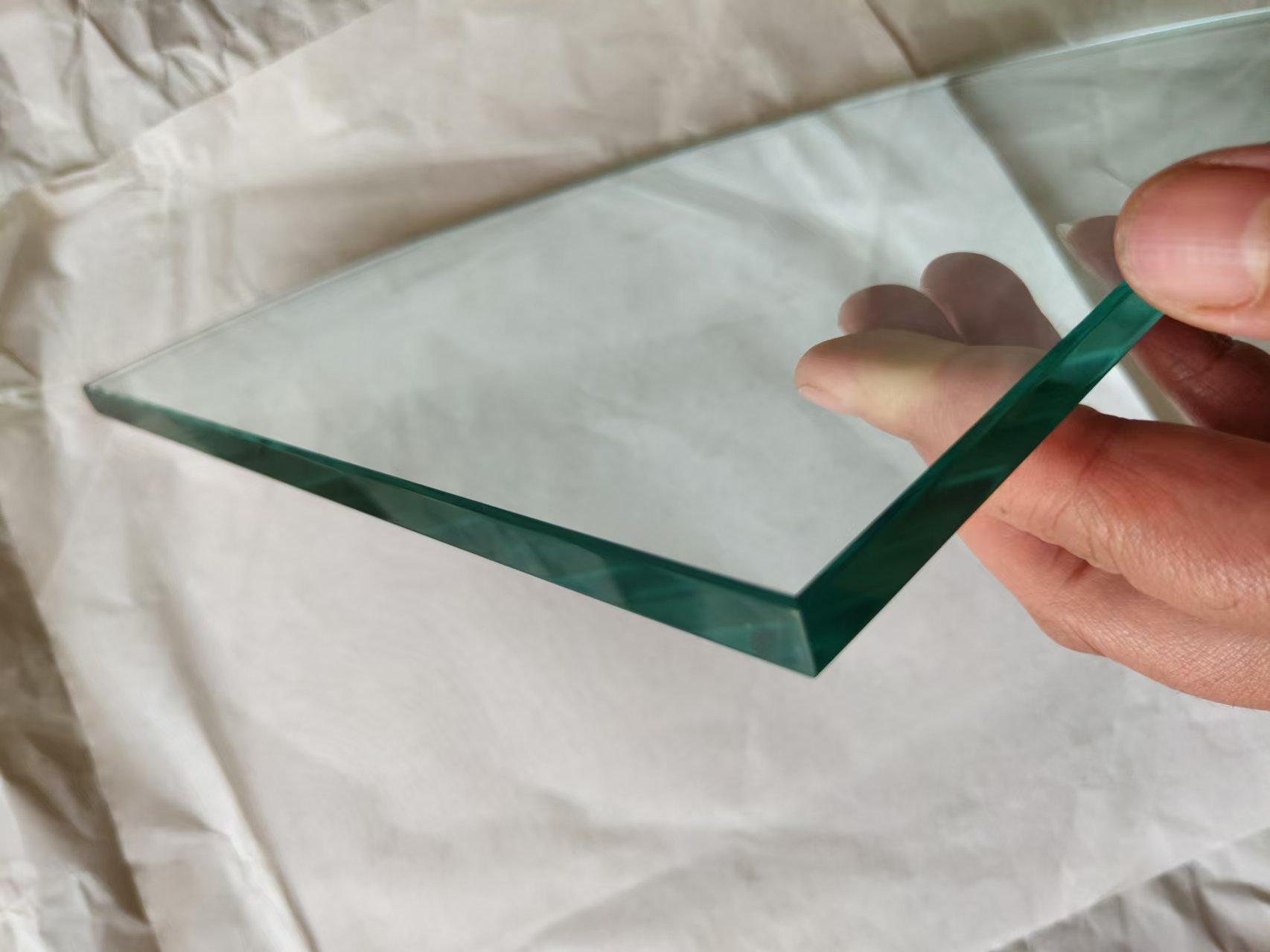

- Excellent Flatness and Optical Quality: Float glass has an exceptionally smooth and flat surface, free from distortions, which results in superior optical clarity and transmission of light. This makes it ideal for applications requiring high visual clarity, such as windows, mirrors, and display screens.

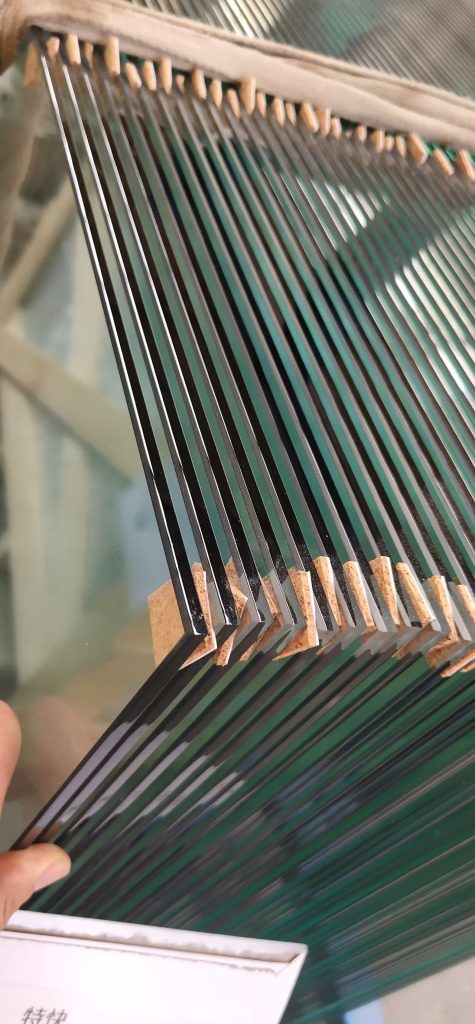

- Uniform Thickness: During the float process, the molten glass spreads evenly across the molten tin bath, resulting in a product with uniform thickness across its entire surface. This consistency ensures that the glass performs uniformly under various conditions.

- Enhanced Strength and Durability: Float glass undergoes a process of annealing, which removes internal stresses and makes it more resistant to thermal shock and breakage. This results in a stronger and more durable product that can withstand weathering and other environmental factors.

- Easy to Process and Fabricate: Due to its flatness and uniformity, float glass is easy to cut, shape, and process into various products and sizes. It can be easily drilled, edged, or tempered to meet specific application requirements.

- Energy Efficiency: Float glass can be coated with various films or treatments to enhance its insulation properties, making it an energy-efficient choice for windows and other building applications. These coatings can reduce heat transfer and improve the overall energy performance of the building.

- Environmentally Friendly: The float glass production process is relatively efficient and clean, with low waste generation. Additionally, float glass is fully recyclable, contributing to a circular economy and reducing the environmental impact of disposal.

- Versatility: Float glass is available in a wide range of thicknesses, sizes, and colors, making it a versatile material suitable for various applications, including automotive, architectural, and consumer goods industries.